Operation

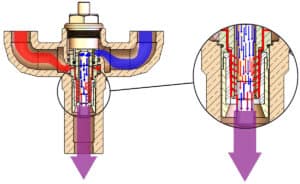

ThermOmegaTech’s STVM® washdown station incorporates unique Venturi mixing technology to deliver water at the required temperature quickly, quietly, and on demand. Cold water enters the upper chamber of the mixing valve, while incoming steam enters the lower chamber. Mixing occurs as the two vortices collide, thoroughly mixing and heating the water through a Venturi diffuser with minimal noise and vibration.

Conventional washdown mixing stations that rely on multiple moving parts and use old spool and diaphragm technology are prone to premature failure due to mineral deposits and scaling. The necessary regular maintenance of these units to keep them running safely is very time-consuming and costly. The rugged STVM® mixer is unique because it has only one moving part, a thermal actuator within the mixing valve cartridge.

The patented mixing design ensures extended, uninterrupted use even if the water contains high mineral content. As the opposing vortices of steam and water enter the mixing valve, a scouring action occurs that minimizes the buildup of minerals and scale.

The Safe, Efficient Steam Water Mixing Station

An additional benefit of this design is what you don’t hear: the banging, popping, and crackling noises associated with cavitation that are prevalent in ordinary mixing stations. This smooth, quiet operation increases safety and reduces stress on the operator.

Safety is our priority, so every STVM® Washdown Station has two built-in safety features – interlocking ball valves to prevent steam-only operation and an automatic shut-off when output is 15°F over the unit’s temperature set-point (either 150°F or 185°F) or when cold water flow is interrupted.

Typical Applications

The STVM® steam and water mixer station is used for cleaning processing machinery or chemical tanks and equipment in food processing, dairy, breweries, wineries, chemical, petrochemical, and pharmaceutical facilities where high-temperature steam and cold water mixer stations are required.

Design Features

- Exclusive self-actuating Thermoloid® wax blend thermal actuator

- Interlocking ball valves prevent steam only operation

- Thermally activated over-temperature shut-off

- Unique Venturi mixing design minimizes water hammer effect

- Check valves, stainless steel thermometer, globe valves, and stainless-steel hose rack, standard with all units

- 6.5” (165.1 mm) center line to center line pipe dimension. Optional 1/4” offsets are available to adapt to existing 6.0” center line piping

Benefits

- Self-operating – no external power source required

- In-line serviceable mixing valve with easy to replace/clean cartridge – No special tools required

- Quieter operation relieves worker stress

- Resistant to the effects of mineral build-up and scaling

- Automatic steam shut-off when cold water flow is interrupted

- Optional welded Stainless Steel Station available offering superior strength and leak-free sealing for the most demanding applications

- Our stainless steel stations conform with EU Pressure Equipment Directive 2014/68/EU

Ordering

PART NUMBER | DESCRIPTION |

377-111100-150 | ¾” TOT (150ºF (65.6°C)) Stainless Steel Washdown Station |

377-111100-185 | ¾” TOT (185ºF (85°C)) Stainless Steel Washdown Station |

377-111000-150 | ¾” TOT (150ºF (65.6°C)) Brass/Bronze Washdown Station |

377-111000-185 | ¾” TOT (185ºF (85°C)) Brass/Bronze Washdown Station |

377-111170-150 | ¾” TOT (150ºF (65.6°C)) Welded Stainless Steel Washdown Station |

377-111170-185 | ¾” TOT (185ºF (85°C)) Welded Stainless Steel Washdown Station |