Operation – How the Tempering Water Valve Works

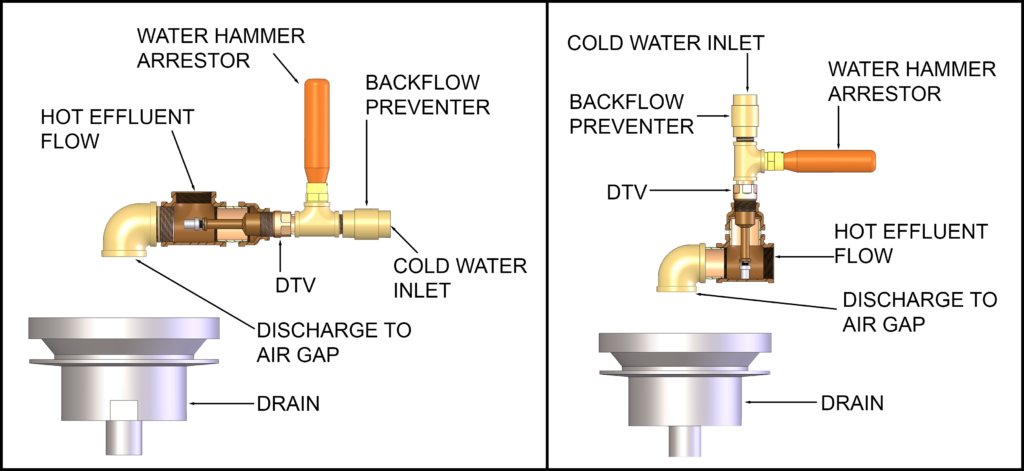

The tempering water valve (DTV drain tempering valve) is installed into the drain line such that the hot effluent passes over the thermal actuator, which controls the cold-water inlet port. If the hot effluent is above the specified set point of the valve, the actuator senses the rising temperature and signals the DTV to open to allow the injection of cold water to temper down the discharge fluid before it reaches the drain.

As the hot effluent cools, the DTV automatically modulates to reduce the cold-water inlet flow. At about 10°F below the full open temperature, the cold-water inlet is fully closed again to conserve water.

The DTV provides a convenient, economical, and easy-to-use method of tempering hot effluent. Since this drain tempering water valve is open only when the effluent exceeds the specified set point temperature, it also conserves water by automatically turning off cold water when not needed.

Typical Applications

A steam condensate drain cooler is an essential component in many industrial processes where steam is utilized to heat a product or process. The DTV drain tempering valve, more specifically, is typically used in commercial dishwashers (warewashers), boiler blowdown drain lines, humidifiers, autoclaves, sterilizers, or any application that discharges scalding water to drains or sewers.

This drain cooler water tempering device ensures water temperatures entering the sewer system do not exceeding 140°F, which can lead to failed inspections, fines, business interruptions, or injury and damage to personnel and equipment.

Design Features

- Exclusive self-actuating Thermoloid® blend paraffin wax actuator

- Rugged, clog-resistant valve design

- Install using standard pipe fittings and tools

- Operates in any orientation

- Modulates to conserve cooling water

- Effluent tempering capacity limited only by cold water flow rate through DTV

Benefits

- Self-operating – no external power source required

- Compliant with drain temperature limitations of plumbing codes

- Prevents damage to PVC piping due to

over-temperature conditions - Minimizes water waste

- Easy to install

- Adaptable to almost any drain size

Choosing Your Size

The DTV valves are available with ½”, ¾”, and 1′′ NPT water connections. To choose the valve right for your system you will need to calculate your Cv. Refer to our DTV FLOW CALCULATOR for assistance.

Recommended Accessories

For DTV installations, most local plumbing codes will require the installation of a check valve or backflow preventer to isolate the drain line from the potable water. A water hammer arrestor must be installed between the DTV and the check valve/backflow preventer if a check valve or backflow preventer is used. Failure to do so may cause permanent damage to the DTV and void the warranty.

ThermOmegaTech offers an optional water hammer arrestor and backflow preventers to make life easier. Contact us or your local representative for more information on these products.

Ordering

PART NUMBER | DESCRIPTION |

325-000000-XXX | 1⁄2” DTV Valve (Brass) |

325-100000-XXX | 1⁄2” DTV Valve (Stainless Steel) |

326-000000-XXX | 3⁄4” DTV Valve (Brass) |

326-100000-XXX | 3⁄4” DTV Valve (Stainless Steel) |

327-000000-XXX | 1” DTV Valve (Brass) |

327-100000-XXX | 1” DTV Valve (Stainless Steel) |

328-000000-XXX | Mini DTV Valve (Brass) |