Operation – How Tepid Water Systems for Safety Showers and Eyewash Stations Operates

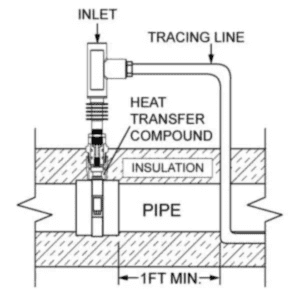

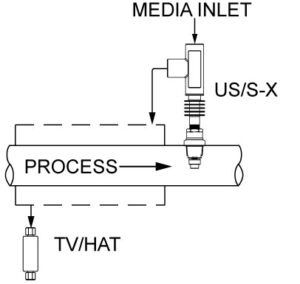

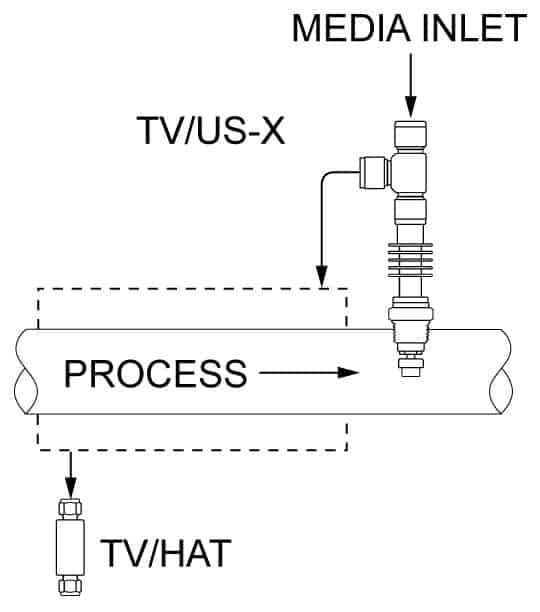

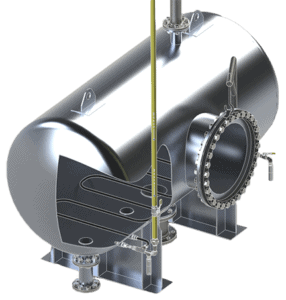

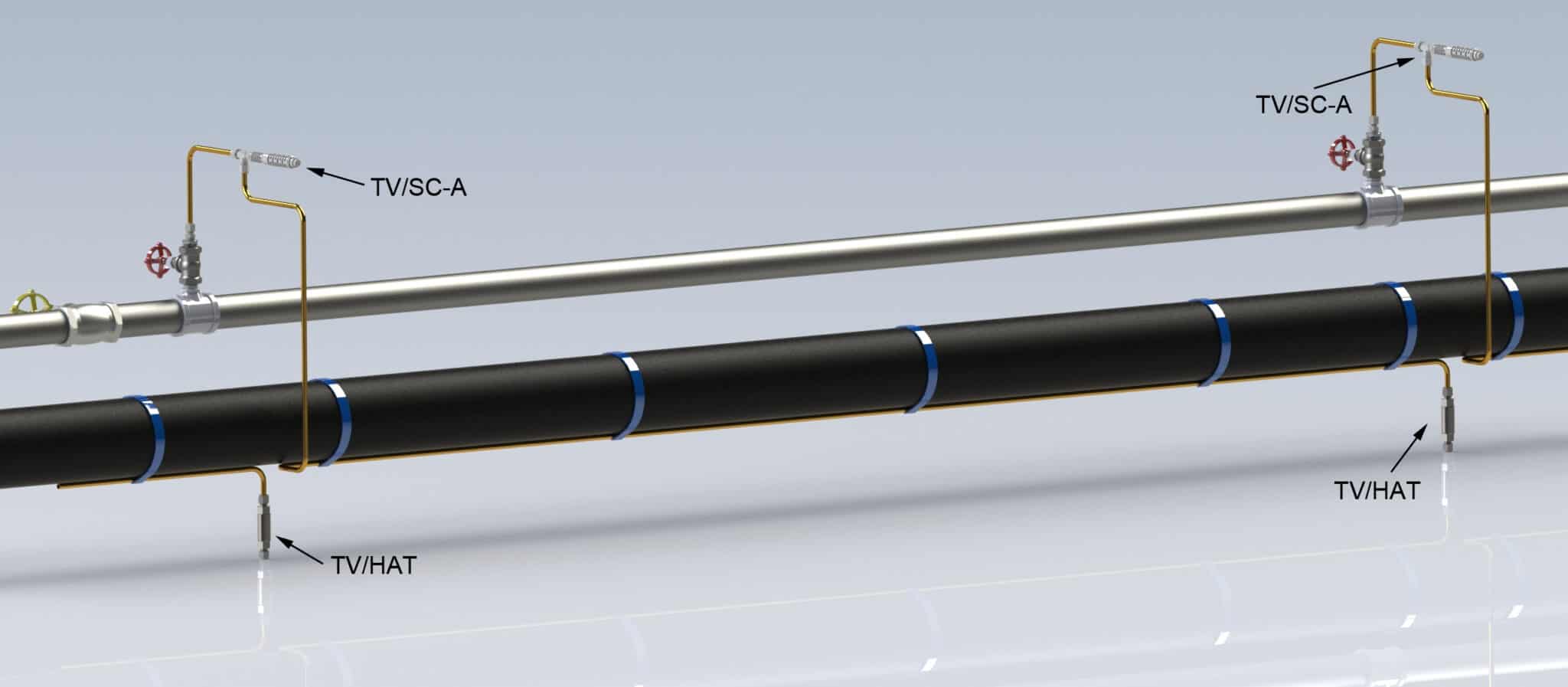

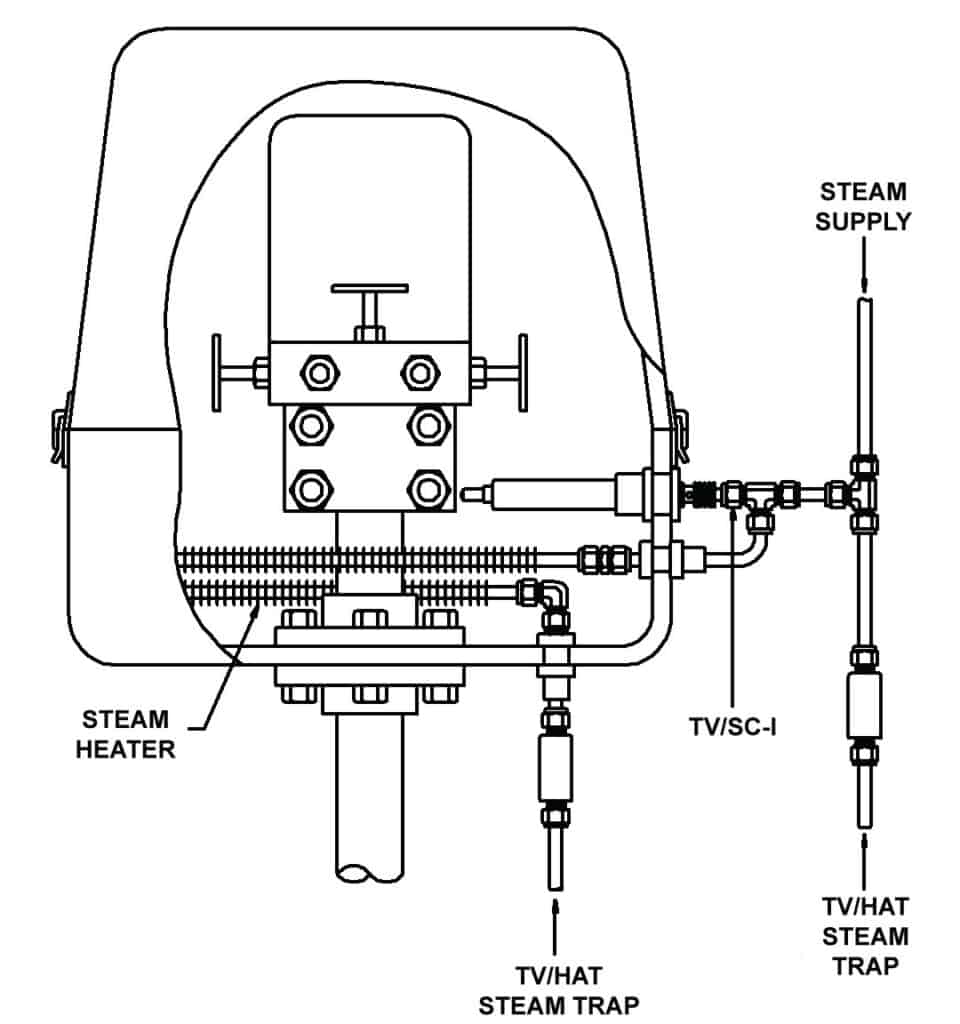

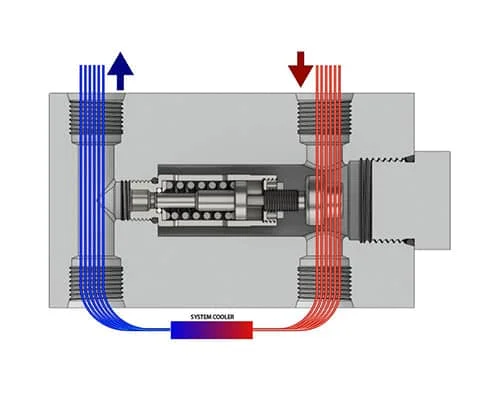

The Therm-O-Mix® tepid water system is designed to deliver tepid water to one shower/eyewash combo at a time. This water heating system should be installed near the shower and piped into a facility’s steam and cold water supply lines.

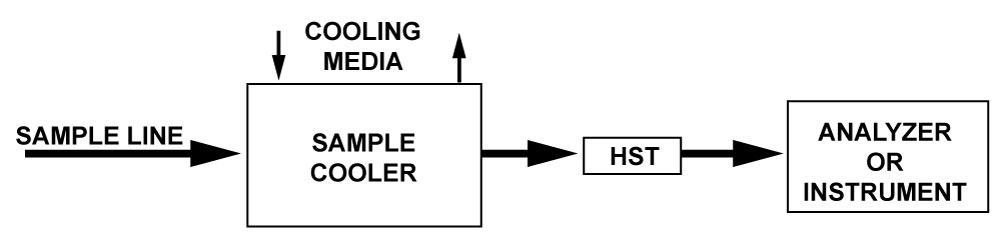

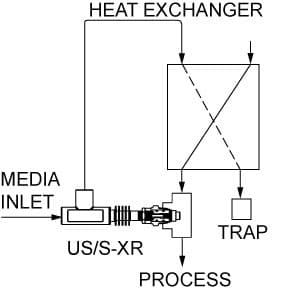

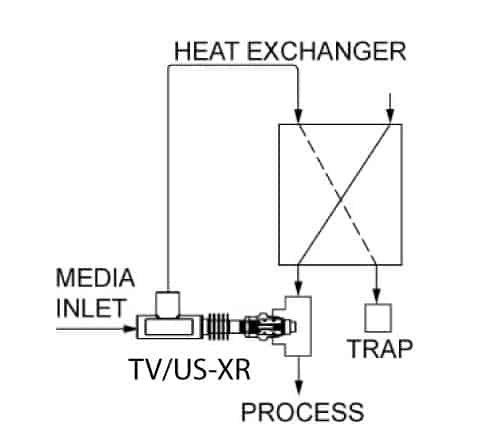

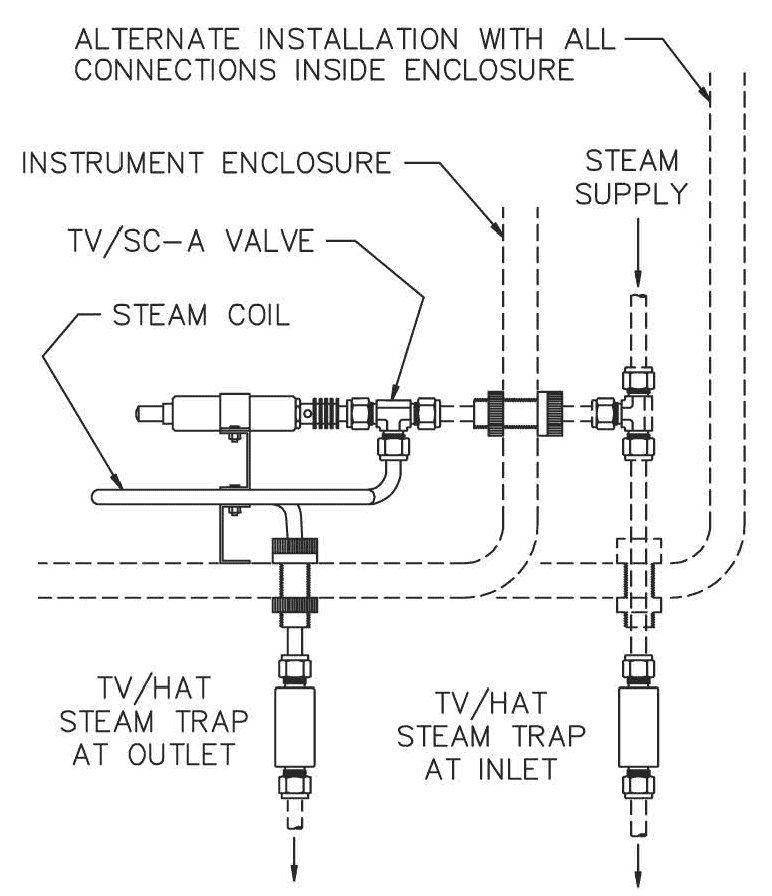

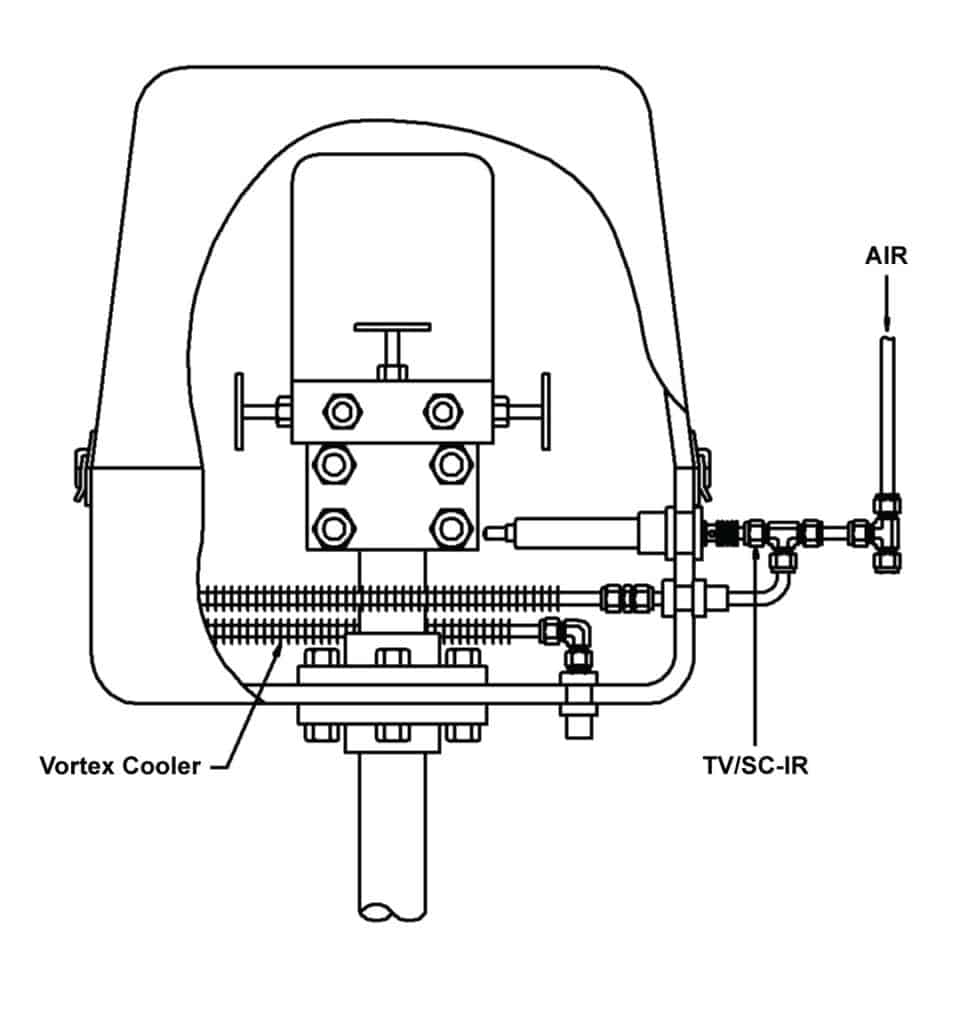

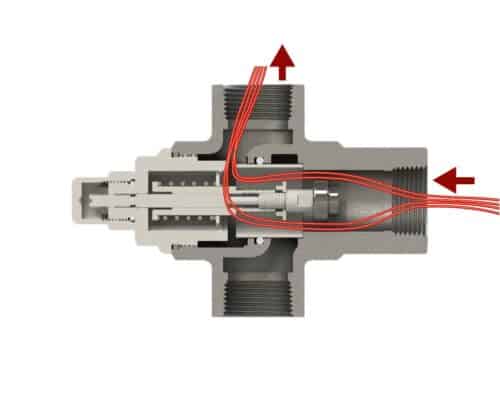

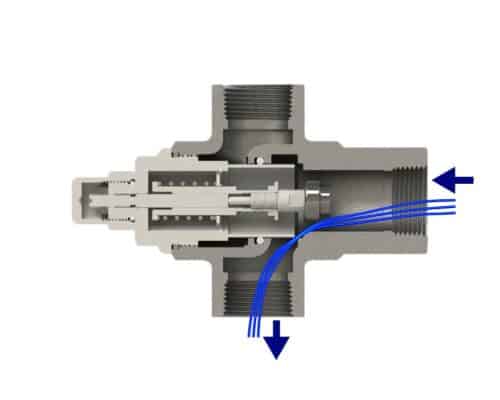

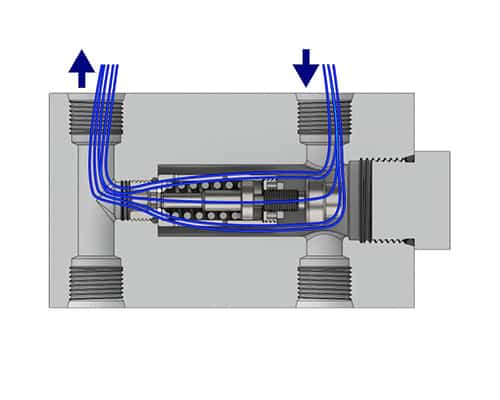

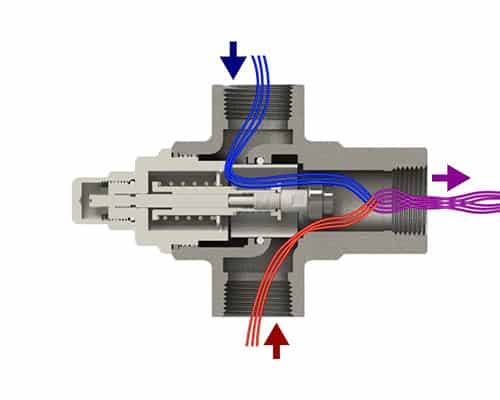

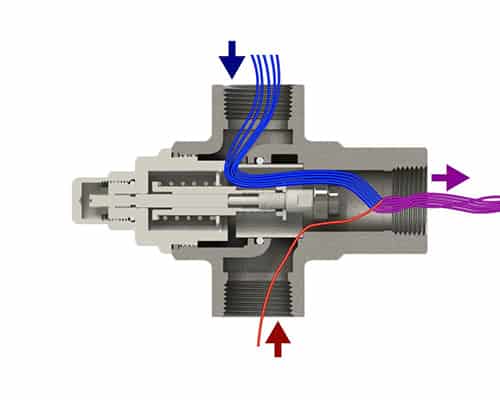

When an emergency shower or eyewash station is activated, the pressure drop on a diaphragm opens the steam control valve (V-3). Water and steam flow are established, instantly heating and condensing the steam. After exiting the heat exchanger, the hot water enters the tempering valve (V-5) and then the mixing valve (V-1), where it is blended with cold water to produce an outlet of 80°F water. The steam valve remains closed should the water supply be interrupted.

Typical Applications

In various industrial and commercial settings, particularly those where dangerous substances are present, OSHA and ANSI mandate the use of tepid water systems for safety showers and eyewash stations. Per their guidelines, all emergency fixtures must provide tepid water for a minimum & continuous 15-minute cycle. Tepid is defined to be between 60°F (16°C) and 100°F (38°C). The Therm-O-Mix® Tepid Water Delivery System can ensure your emergency equipment meets these code requirements by providing 80°F water to protect personnel from scalding or freezing temperatures. Since the station requires no electric power, it is suitable for explosion-proof environments and outdoor installations.

Design Features

- Exclusive self-actuating Thermoloid® wax blend thermal actuator

- Plant steam and water never mix – uses a compact heat exchanger

- Standard pressure unit available for 45-60 PSIG steam pressure

- Low-pressure unit available for 15-30 PSIG steam pressure

- Durable enclosure can be readily removed for service

- Conforms to OSHA and ANSI recommendations

- Designed to meet ASSE 1071 requirements

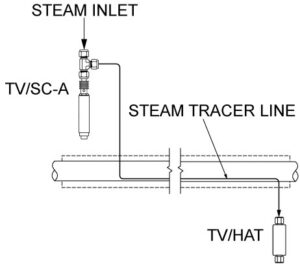

- Steam trap on steam inlet included

Benefits

- Self-operating – no external power source required

- Uses existing plant steam and water supply

- Provides 3 to 25 GPM of 80°F

- Easy to retrofit on existing shower or combination face/eyewash stations

- Maintains constant 80°F output regardless of inlet water temperature

(between 40°F and 80°F) - No insulated tanks or expensive recirculation systems are required

- Self-purging-no need for elaborate drainage system

- Union connections allow quick and easy installation

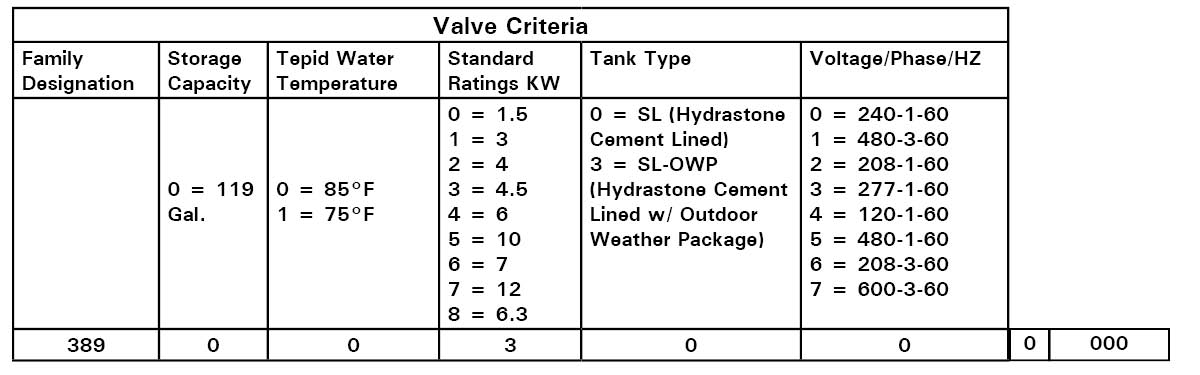

Ordering

PART NUMBER | DESCRIPTION |

387-112100-003 | THERM-O-MIX® STATION, BPHE |

387-512100-003 | THERM-O-MIX® STATION LSP, BPHE |