Operation

The GURU DL 2.1 locomotive freeze protection valve may be thought of as an automatic freeze-out plug with one crucial difference: The stainless-steel GURU® Cartridge releases itself from its body at a pre-set water temperature (35°F or 40°F), rather than being forced out by the tremendous pressure of expanding ice. This provides almost a full one-inch bore to rapidly drain a typical locomotive’s coolant system before damage can occur.

Simply put, the self-operating GURU DL2.1 locomotive freeze protection drain valve continuously monitors and automatically responds to the temperature of the water-cooling system in diesel locomotives. If the water temperature falls to the valve’s set-point, the GURU® Plug will automatically snap open and drain the system before it can freeze.

Resetting and rearming the GURU® Plug is easily accomplished by reheating the cartridge and reinserting it into the hex nut. We recommend utilizing our GURU® Flag and Clip or GURU® Flag and Key tool during the refill process to prevent the GURU® Plug from triggering open by the cold water during the refill.

These tools provide a visual indicator that a refill process is in place and prevents personnel from using a penny, washer, zip tie, or another method to keep the valve stem in place. These “tools” could result in personnel forgetting to remove them before the locomotive goes back into service and possibly result in freeze damage to the locomotive down the line.

Typical Applications

Diesel locomotives depend on reliable freeze protection solutions to get them through the winter. Without a drain valve that can be trusted to operate correctly, locomotives can suffer catastrophic damages, resulting in expensive repair and schedule delays.

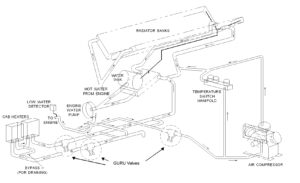

The self-actuating GURU® DL2.1 eliminates the risk of freezing in locomotives, compressor set cooling systems, stand-by diesel heating circulators, hot water cab heater lines, and onboard tanks and piping.

Design Features

- Exclusive self-actuating Thermoloid® blend paraffin wax actuator

- Thermal actuator sensing surface is the only wetted part

- Long service life: All moving parts are stainless steel

- Design excludes cooling water chemicals and other debris from moving parts

- Several body styles are available for various applications: 1-1/4 NPT, tee, and flanged tee.

- Paint mask minimizes accidental paint-ins

- Knob on cartridge for easy installation and removal even in hard-to-reach locations

- Extra port for temperature bushing

- Choice of release temperatures: 35°F / 40°F

Benefits

- Self-operating – no external power source required

- Will not trip or dump while the locomotive is running

- Not affected by airflow or air temperature surrounding the valve

- Rapid draining

- Easy system refill

- Easily maintained and tested in the field

- Slotted actuator feature prevents nuisance dumps when refilling the cooling system with cold water

- Valve automatically rearms after filling and reheating

- Optional domed anti-tamper cap eliminates the ability to tamper with the valve resetting stem