Mechanical seals play an important role in industrial processes. They prevent fluid leakage and maintain system integrity in pumps and rotating equipment. However, these seals are susceptible to overheating, abrasion, and dry running, especially in high-demand environments. Excessive heat can degrade seals, leading to failure and unplanned maintenance, while excessively cold fluid can increase viscosity and reduce efficiency.

Mechanical seal support systems mitigate these risks by controlling cooling, lubrication, and regulating temperature. These systems ensure that seals operate within an optimal temperature range, reducing wear and extending their lifespan. Without proper temperature management, mechanical seals that rely on cooling water may waste thousands of gallons annually, leading to higher operational costs and increased environmental impact.

A well-designed mechanical seal support system helps:

- Maintain continuous and reliable operation

- Minimize system breakdowns from overheating or dry-running

- Ensure proper lubrication for optimal seal performance

- Prevent excessive wear leading to costly failures

- Improve overall equipment efficiency and longevity

By proactively managing the temperature of seal cooling water, facilities can optimize water consumption, eliminate unnecessary waste, and reduce maintenance-related expenses.

Typical Mechanical Seal Applications

Mechanical seals are used in industrial industries such as food and beverage, pharmaceutical, and chemical processing, which rely on pumps, mixers, and reactors to handle various substances. Proper thermal management is crucial in these applications to ensure smooth operations, prevent contamination, and comply with strict industry regulations.

For example, pumps transport liquids such as syrups and soda in food and beverage processing, often requiring mixers and agitators to maintain consistency. Without proper mechanical seal temperature control, these processes can suffer from inefficiencies, increased maintenance, and potential product contamination. Similarly, in pharmaceutical production, maintaining precise thermal conditions within processing equipment is essential to uphold sterility and product integrity.

By incorporating a seal support system, facilities can enhance equipment performance, reduce downtime, lower maintenance costs, and ensure regulatory compliance across various industries.

The Benefits of Self-Actuating Seal Support Valves

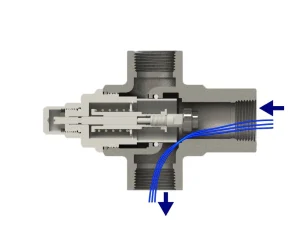

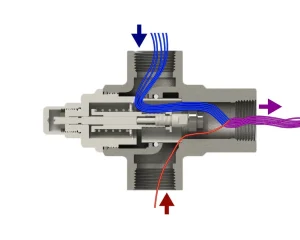

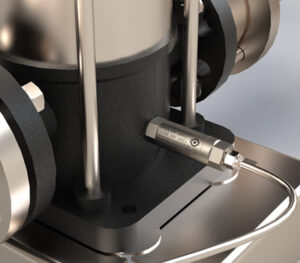

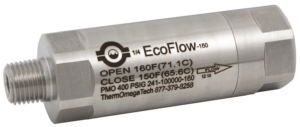

One effective solution for protecting pump seals is ThermOmegaTech’s EcoFlow® Mechanical Seal Support Valve.

Installed on the seal’s water outlet, this valve automatically regulates a constant water outlet temperature, ensuring that it remains within the ideal operating range.

Unlike manually adjusted or electronically controlled systems, self-actuating valves operate independently, responding in real time to temperature fluctuations.

The EcoFlow® valve monitors water temperature and automatically adjusts the water required, preventing overheating and seal failure. Since it operates thermostatically, there is no need for external power or continuous human oversight, reducing operational errors such as manually opening or closing water valves.

Implementing a thermal management valve offers several advantages:

- Consistent Seal Support – Maintains a steady water outlet temperature to protect seals from thermal damage.

Water Conservation – Reduces unnecessary water use, lowering operational costs.

Water Conservation – Reduces unnecessary water use, lowering operational costs.- Reliable Performance – Operates thermostatically without external power, making it ideal for demanding industrial applications.

Boost Efficiency and Reduce Water Consumption

Reducing seal water consumption lowers water usage, enhancing system reliability and decreasing maintenance expenses.

The self-operating EcoFlow® valve protects seals by using water only when necessary. This water-conserving seal support system reduces operating costs, making it a cost-effective solution for protecting mechanical seals and saving significant amounts of water.

Optimizing Water Usage in Industrial Processing with EcoFlow®

Efficient cooling water management is a critical concern for industrial processing facilities, particularly in the food and beverage sector, where water usage directly impacts operational costs and sustainability goals.

Efficient cooling water management is a critical concern for industrial processing facilities, particularly in the food and beverage sector, where water usage directly impacts operational costs and sustainability goals.

A major U.S. sugar producer faced excessive water consumption due to inefficient seal water flow in their processing pumps, leading to high operational expenses and water waste.

By implementing ThermOmegaTech’s EcoFlow® Mechanical Seal Support Valve, they achieved a 50% reduction in seal water usage, leading to:

- Lower operational costs

- Improved sustainability metrics

- Reduced maintenance requirements

The success of this project demonstrates how innovative and consistent thermostatic solutions like EcoFlow® can drive productivity, lower operational costs, promote water conservation, and support sustainability initiatives.

As industries continue to seek ways to optimize resource consumption, EcoFlow® provides a reliable and cost-effective solution for mechanical seal water management.

Conserve Water Usage and Save!

Reduce water consumption, lower costs, and improve efficiency with ThermOmegaTech’s EcoFlow®, our mechanical seal thermal management valve. Our advanced thermostatic valves ensure precise temperature control, protecting equipment while conserving resources.

Discover how our forward-thinking water conserving seal support system can enhance your operations—Learn More Now!