Social Responsibility

“Shotgun Fred’s Guru Crew” The Walk to Defeat ALS!!

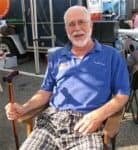

Fred Pirkle, aka “Shotgun Fred”, founded ThermOmegaTech® in 1982.

Since then, he has patented more than 20 products, including the first temperature control device for charcoal grills/cookers – hence “The BBQ Guru” was born in 2004.

In April 2011, Fred was diagnosed with ALS. As his friends and family are well aware, he is a fighter and continues to fight the disease every day. ALS, or amyotrophic lateral sclerosis, is a progressive neurodegenerative disease that affects nerve cells in the brain and spinal cord.

In Fred’s honor, and in an effort to help support patient service programs and ALS research, ThermOmegaTech® and The BBQ Guru have joined forces with the ALS Association.

We are a corporate sponsor of and have formed a team, “Shotgun Fred’s Guru Crew.” On Saturday, November 5th, we participated in our first Walk to Defeat ALS.

For more information about ALS, Social Responsibility, or this event please go to www.alsphiladelphia.org

Frederick (Fred) L. Pirkle, owner of ThermOmegaTech, Inc., in Warminster, PA passed away March 9th at his home.

Frederick (Fred) L. Pirkle, owner of ThermOmegaTech, Inc., in Warminster, PA passed away March 9th at his home.

The

The

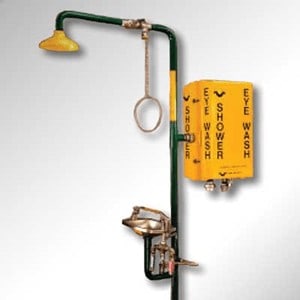

Keeping your safety shower working at optimum performance is important, no matter what time of year. However, cold winter temperatures can make this especially difficult. Water can freeze in supply lines, clogging the system and shutting off flow. And because water expands as it freezes, internal pressure in the line can increase enough to break steel pipes and their associated valves and fittings. The result can be costly replacement parts, in- creased labor costs, and a shower that’s out of commission while it’s being repaired.

Keeping your safety shower working at optimum performance is important, no matter what time of year. However, cold winter temperatures can make this especially difficult. Water can freeze in supply lines, clogging the system and shutting off flow. And because water expands as it freezes, internal pressure in the line can increase enough to break steel pipes and their associated valves and fittings. The result can be costly replacement parts, in- creased labor costs, and a shower that’s out of commission while it’s being repaired.