Operation

Installed at the lowest point or dead leg branch, HAT/FP utilizes our thermostatic wax actuator technology to monitor ambient or water temperatures automatically and will bleed off the cold water in the lines before freezing can occur. HAT/FP freeze protection valves initiate flow when the thermostatic actuator senses the valve’s set-point, typically 35°F (1.6°C), and will remain open as long as the discharge water temperature is below 5 degrees above that, typically 40°F (4.4°C).

DEPENDING ON THE APPLICATION NEEDS, the HAT/FP freeze protection valve can be installed in either the standard or reverse flow orientation. In standard flow orientation, the wax actuator will sense the ambient temperature to initiate flow and then respond to water temperature once flow is established. In reverse flow orientation, the wax actuator will sense the water temperature at the point of installation to initiate flow and continue to respond to water temperature once flow is established.

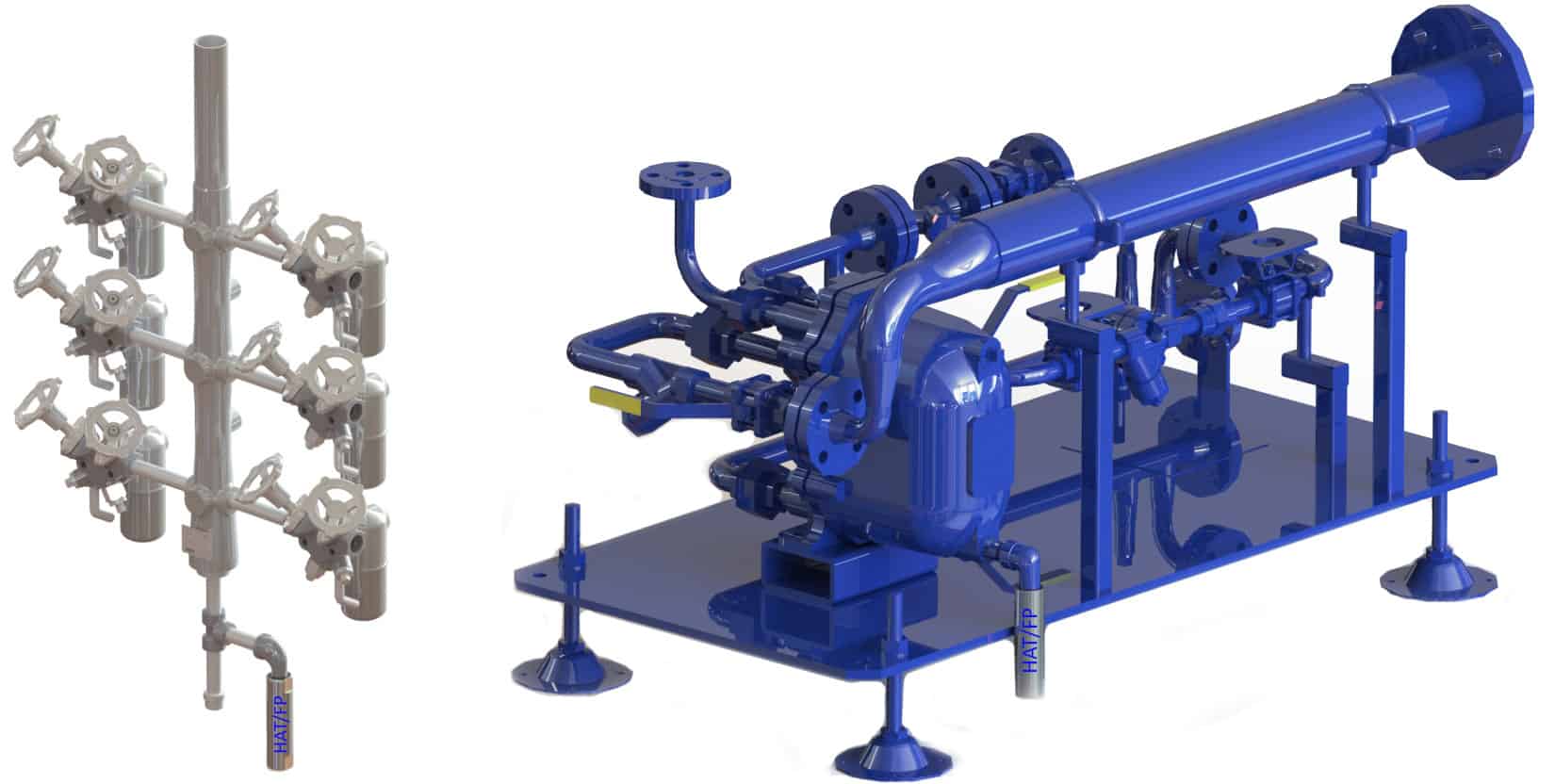

Typical Applications

Relying on manually opening valves for freeze protection allows for human error or plugging partially cracked valves. This annually accounts for large amounts of freeze damage resulting in huge monetary losses, including repairing damaged equipment and piping and system downtime.

The self-actuating HAT/FP valve eliminates the human errors associated with manual valves. Automatic freeze protection valves are ideal for protecting piping, safety showers, eyewash or facewash stations, solar collectors & piping, condensate systems, fire lines, spray nozzles, or as backup/fail-safe protection on traced systems.

Design Features

- Exclusive self-actuating Thermoloid® blend paraffin wax actuator

- Corrosion-resistant

- Narrow temperature band

- Compact and low mass

- Stainless steel body, fittings, spring, and plug

- Two wrench flats for easy installation

- Ram-type plug for reliable shutoff

Benefits

- Self-operating – no external power source required

- Protects against freeze damage

- Primary protection or fail-safe backup

- Long service life

- Fast response

- Discharges minimum amount of water required

- Some valves are NSF/ANSI/CAN 61 & 372 Certified

Ordering

PART NUMBER | DESCRIPTION |

114 - 212100 - 035 | ½” HAT/FP-35-B-SS-E (Ambient Sensing) |

114 - 812100 - 035 | ½” HAT/FP-35-B-SS-RF-E1(Fluid Sensing) |

114 - 302100 - 035 | ½” HAT/FP-35-C-E (Ambient Sensing) |

114 - 702100 - 035 | ½” HAT/FP-35-C-RF-E2 (Fluid Sensing) |

114 - 312100 - 035 | ½” HAT/FP-35-C-SS-E (Ambient Sensing) |

114 - 712100 - 035 | ½” HAT/FP-35-C-SS-RF-E2 (Fluid Sensing) |

115 - 502100 - 035 | ¾” HAT/FP-35-D-E (Ambient Sensing) |

115 - 512100 - 035 | ¾”HAT/FP-35-D-SS-E (Ambient Sensing) |

115 - 712100 - 035 | ¾” HAT/FP-35-D-SS-RF-E2 (Fluid Sensing) |