INDUSTRIAL

Thermostatic

Temperature Control

Valves

RAILROAD

Guru®

Freeze Protection

Valves

PLUMBING

CircuitSolver®

Balancing & Drain

Tempering Valves

AEROSPACE & DEFENSE

Thermal Actuators

Thermostatically Controlled

Valves

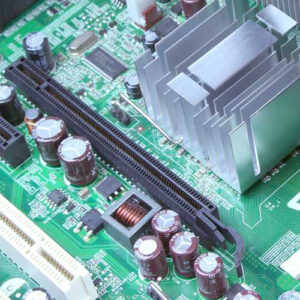

ELECTRONICS

Custom PCB Assembly

Aerospace, Defense &

Commercial Markets

Thermostatic Temperature Control Valves

ThermOmegaTech® is a leading designer and manufacturer of highly reliable thermostatic temperature control valves and thermal actuators. Beginning in Railroad and expanding into the Industrial, Commercial Plumbing, Aerospace, and Defense markets over the last 40 years, we have successfully implemented our thermostatic solutions to precisely monitor and control fluid based on temperature in dozens of applications.Popular applications include freeze and scald protection, tepid water, washdown, steam tracing control, thermal balancing, mixing, diverting, drain tempering, and more.Our main goal is to supply our customers with the highest quality products while providing excellent customer service. We do this by maintaining a quality management system that is certified to AS9100D standards for the aerospace industry and ensuring rapid responses and an individualized customer support experience with our sales and technical teams.

ThermOmegaTech® is a leading designer and manufacturer of highly reliable thermostatic temperature control valves and thermal actuators. Beginning in Railroad and expanding into the Industrial, Commercial Plumbing, Aerospace, and Defense markets over the last 40 years, we have successfully implemented our thermostatic solutions to precisely monitor and control fluid based on temperature in dozens of applications.Popular applications include freeze and scald protection, tepid water, washdown, steam tracing control, thermal balancing, mixing, diverting, drain tempering, and more.Our main goal is to supply our customers with the highest quality products while providing excellent customer service. We do this by maintaining a quality management system that is certified to AS9100D standards for the aerospace industry and ensuring rapid responses and an individualized customer support experience with our sales and technical teams.

PCB Assembly Contract Manufacturing

We have expanded into the Electronics Contract Manufacturing market, specializing in custom Printed Circuit Board assembly services. We offer various PCB types and technologies using automated and manual techniques for placing PCB components to meet the most rigorous design requirements for aerospace, military, and commercial markets. Visit our Electronics Division’s website to learn about our capabilities.

Our Technology

At the heart of each of our temperature flow control valves is a paraffin wax actuator, an “engine” that phase changes from solid to liquid, liquid to solid, in response to temperature variations. This produces a defined and repeatable valve modulation, allowing for precise thermal control based solely on temperature.

Learn More

Case Studies

Our self-acting temperature control valves are used in applications in railroad, commercial plumbing, aerospace, defense, and industrial markets in thousands of projects and products each year – ranging from fighter jets to commercial dishwashers and just about everything in between.

Read our case studies to see where our valves are, what they do, and what our customers say about us!

Testimonials

Testimonial 11

A typical steam tracing system using ThermOmegaTech’s® thermostatic steam trap valves can expect to save at least $354 per valve, per year.

Electric vs. Steam Tracing Case Study

Testimonial 10

After the successful CircuitSolver® installation, St. Elizabeth Healthcare Edgewood now has access to an on demand hot water supply in all wings, on every floor, at every fixture.

CircuitSolver® installation, St. Elizabeth Healthcare Edgewood

Testimonial 9

Hot water is now available throughout the entire main pavilion on demand.

CircuitSolver® installation, The University Institute of Mental Health (IUSMQ)

Testimonial 8

Soon after startup, the facility was supplied with hot water throughout the building without any balancing procedures.

CircuitSolver® installation, Inspira Health

Testimonial 7

The system is efficiently delivering hot water to over 70 fixtures, of which include showers, sinks, safety showers and mop basins.

CircuitSolver® installation, Berks Center for Digestive Health

Testimonial 6

Residents are more than pleased with hot water delivery times after the installation. Units with wait times of multiple minutes saw a dramatic reduction, fixtures now reached proper temperature in 20-30 seconds.

CircuitSolver® installation, The Austonia

Testimonial 5

After testing a preliminary unit for more than a year, the regional rail operator installed 186 1” GURU PC®’s with heater assemblies […] and the project manager commented that since the installation there have been no freeze-ups.

Guru PC® Installation, Chicago Area Commuter Regional Rail Operator

Testimonial 4

The Therm-O-Mix® Station was selected […] to promote overall conformity of safety equipment and procedures. Installation of 26 integrated units is currently underway at the facility and will be completed by the end of 2019.”

Therm-O-Mix Installation, Canadian Chemical Production Facility

Testimonial 3

ThermOmegaTech‘s engineers worked one-on-one with the customer, overcoming roadblocks to design a solution that satisfied all the project’s requirements […] After successful prototype testing, the customer implemented this custom thermal bypass valve into hundreds of military vehicles.

Custom Designed Hydraulic Thermal Bypass Valve

Testimonial 2

We could not use a seal before because we could not allow more than a couple gallons an hour of water to the drain. Your valve dramatically decreases the water usage and as a result reduces the amount we send to drain.

EcoFlow Installation, Major US Sugar Producer

Testimonial 1

We needed consistent hot water for sanitation and we really liked the cartridge technology. The washdown stations were easy to install and run effectively.

STVM® Washdown Station Installation, Dave Treuthardt, Wisconsin Cheese Group

Join Our Newsletter!

Sign up to receive the latest info on our products, applications, case studies & more!

Select Your industry and Enter Your Email Address:

ThermOmegaTech® is a leading designer and manufacturer of highly reliable thermostatic temperature control valves and thermal actuators. Beginning in Railroad and expanding into the Industrial, Commercial Plumbing, Aerospace, and Defense markets over the last 40 years, we have successfully implemented our thermostatic solutions to precisely monitor and control fluid based on temperature in dozens of applications.Popular applications include freeze and scald protection, tepid water, washdown, steam tracing control, thermal balancing, mixing, diverting, drain tempering, and more.Our main goal is to supply our customers with the highest quality products while providing excellent customer service. We do this by maintaining a quality management system that is certified to AS9100D standards for the aerospace industry and ensuring rapid responses and an individualized customer support experience with our sales and technical teams.

ThermOmegaTech® is a leading designer and manufacturer of highly reliable thermostatic temperature control valves and thermal actuators. Beginning in Railroad and expanding into the Industrial, Commercial Plumbing, Aerospace, and Defense markets over the last 40 years, we have successfully implemented our thermostatic solutions to precisely monitor and control fluid based on temperature in dozens of applications.Popular applications include freeze and scald protection, tepid water, washdown, steam tracing control, thermal balancing, mixing, diverting, drain tempering, and more.Our main goal is to supply our customers with the highest quality products while providing excellent customer service. We do this by maintaining a quality management system that is certified to AS9100D standards for the aerospace industry and ensuring rapid responses and an individualized customer support experience with our sales and technical teams.